3.832,31 €

Ozonator in Continuous Bottling 30 L /min 0,3 – 0,8 ppm 4000 mg/O3/h

- Description

- Additional information

Description

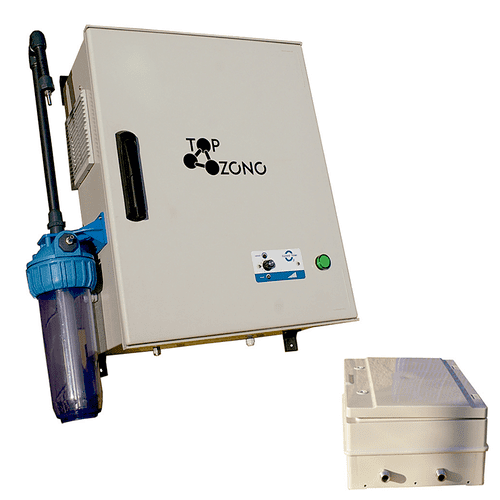

Ozonizers in Continuous Bottling

It consists of the generator module of Ozone reactors, stainless steel, Kit Venturi sensor, water flow and water trap with capacitive sensor, solenoid valve and electronic control, mounted externally. Incorporates counter-Liter. Filtration of air by molecular sieve and Box-monoblock Polyester. Can be mounted in a cart to make it portable.

We recommend to feed the generator with oxygen to ensure the quality of the mixture.

-Maximum pressure supported: 2 to 4 bar

-Concentrations: 0.3 to 0.8 ppm, depending on the quality of the water.

Results

-Oxidation of Iron and Manganese.

-Reduction of Salts of heavy.

-Removal of color, taste, smell

-Reduces turbidity, suspended solids content and the demands chemical (COD) and biological (BOD) of oxygen.

-Removal of Algae.

-Oxidation of Organic Phenols, Detergents, Pesticides).

-Microfloculación of organic solvents.

-Oxidation of Inorganic (Cyanides, Sulfides and Nitrites).

-Reduction of Trihalomethanes, and other items organ-chlorinated.

Advantages of the treatment

-It is very fast and effective, well above that of other treatments

-Is a treatment that is eco-friendly, and respectful of the environment

-The systems of generation of ozone do not require additional chemicals

-The systems have a minimum of maintenance

For treatment of ozonated water in the lines of flow of water. Systems are very easy to install, since they only require connection to the electrical network, a water inlet and an outlet free. In the output connects to the hose that normally use. So, all of the flow that passes through the machine exits immediately through the mouth of an output and the attached hose, transformed into ozonated water. Both for use with fresh and salt water.

Generators Top Ozone does not produce aluminum, very toxic heavy metal, as they do not employ reactors ceramic but made of stainless steel.

Designed for pressures of 2 to 4 atmospheres.

Despite not being designed for use as degreasers, help to break down the fat, but for degreasing should be used other methods, such as hot water, then finish the disinfection with these machines.

Technical Characteristics

| Model | Flow rate | ppm | Production O3/h |

| G-H2O-C-15 | 15 L / minute | 0.3 to 0.8 | 2000 mg |

| G-H2O-C-30 | 30 L / min | 0.3 to 0.8 | 4000 mg |

| G-H2O-C-80 | 60 – 80 L / min | 0.3 to 0.8 | 12000 mg |

Additional information

| Weight | 63 kg |

|---|---|

| Dimensions | 90 × 70 × 50 cm |